What you’ll learn:

- How GaN and SiC have enhanced performance capabilities.

- How test and measurement advances help meet current challenges.

- The technologies and tools that are simplifying the test process for engineers.

The growing power electronics market is being driven by wide-bandgap (WBG) semiconductors like gallium nitride (GaN) and silicon carbide (SiC), which are now being employed in demanding applications such as automotive and RF communications. SiC and GaN offer enhanced performance capabilities including higher power density, smaller size, better high-temperature performance, higher frequency response, lower leakage, and lower on-resistance than silicon, all of which add up to greater operating efficiency.

Traits of GaN and SiC

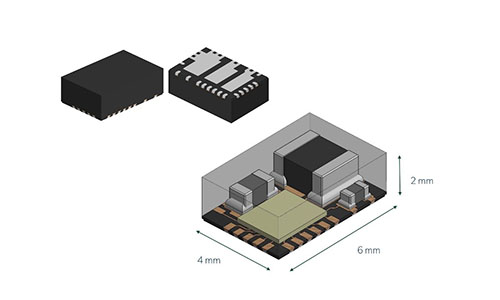

GaN has helped reduce size while increasing power density, improving the battery charge time in everything from cell phones and hand power tools to portable personal healthcare monitoring systems. WBG devices are well-suited for fast charging of devices thanks to reduced conduction losses and faster switching speeds. GaN is a primarily a good fit for low- to mid-range power implementations (under approximately 1 kV and 100 A) such as LED lighting and RF power amplifiers.

The technologies surrounding SiC are more developed than GaN and better suited to higher power implementations such as power transmission, large-scale HVAC equipment, and industrial systems. Compared to silicon MOSFETs, SiC MOSFETs provide higher performance, efficiency, power density, and reliability. This combination of benefits helps designers reduce the size, weight, and cost of power converters, making them more competitive, especially in lucrative market segments such as aerospace, military, and electric vehicles.

Transitioning from traditional silicon to WBG semiconductors results in power-module designs that can be physically smaller, while also increasing MOSFET switching speed and energy efficiency. As competitive pressures make these design parameters more critical, design engineers must reevaluate their approaches to validation and testing.

Need for More Rigorous Testing

While the types of testing that are required during the design and production of power converters resemble those for previous generations of devices, the adoption of WBG materials means added rigor in that testing is needed.

Engineers continue to demand higher measurement accuracy and the ability to better understand the clamor for higher power densities and efficiency(see figure). The drive for energy efficiency is a particularly significant contributor to the need for added rigor in testing. Moreover, data measurements must be robust enough to meet regulatory and certification requirements, as well as current JEDEC JC-70 Wide Bandgap Power Electronic Conversion Semiconductor standards.

测试和测量工具的进步,比如arbitrary function generators (AFGs), oscilloscopes, source-measure-unit (SMU) instruments, and parametric analyzers are helping power design engineers obtain more robust results more quickly. This updated equipment helps them meet daily challenges, such as:

- Simplify test setup to reduce measurement errors

- Reduce measurement times to extract switching parameters

- Increase measurement accuracy for the design of high-efficiency converters

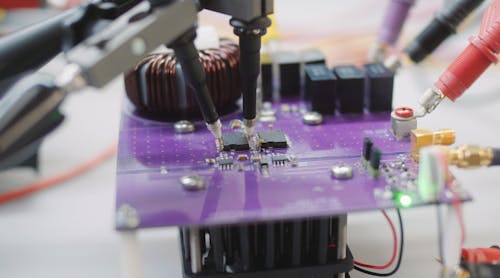

Minimizing switch losses continues to be a major challenge for power-device engineers; these designs must be rigorously measured to ensure compliance. One key measurement technique is called the double pulse test (DPT), which is the standard method for measuring the switching parameters of MOSFETs or IGBT power devices.

Double Pulse Test

The DPT can be done using an AFG and oscilloscope. However, historically, it’s been a time-consuming process to set up because function generators don’t usually have a built-in way to configure and set up the test. This is changing now, though, with newer AFGs including a built-in software application that enables DPT right from the touchscreen interface of the instrument, dramatically simplifying the process for engineers.

随着世界变得更加紧密和我们的技术logy adapts, so too must our engineering tools and techniques. Testing tools and techniques of old will simply not be sufficient. And without the ability to measure critical values and ensure the functionality of important devices, our progress can only go so far. Fortunately, advances in test and measurement tools are keeping pace with the evolution of WBG devices, providing engineers with the precise data needed to make good decisions.

_pushing_performance_beyond_silicon.png?auto=format,compress&fit=crop&h=139&w=250&q=45)