This article is part of the能源管理系列:深入电力密度

你会学到什么:

- 用于嵌入3D包装以提升功率密度的各种技术。

- Different methods for cooling chips using 3D packaging.

在印刷电路板(PCB)级别部署了用于3D包装的新的和新兴技术。通过组件集成,可以将功率密度的目标简化为使用堆叠技术,集成,转置器等的芯片刻度包。先进的冷却方法有助于使3D包装成为可行的选择。

最新的技术创新和冷却方法将提高新设计中的功率密度,并在旧设计中升级。在本文中,这些创新和方法将大大提高3D动力包装中的功率密度。

Embedding and Integrating

面朝上/面朝下

Present-day technology enables embedding of such things as active and/or passive components, magnetics, and integrated filters into the circuit board.

Texas Instruments' MicroSIP was the first commercial dc-dc converter produced with theHERMES“face down approach.” The HERMES project aims at embedding active dies, face up or face down (flip chip), and (thin) passive components inside the dielectric layers of a PCB.

Embedding magnetics

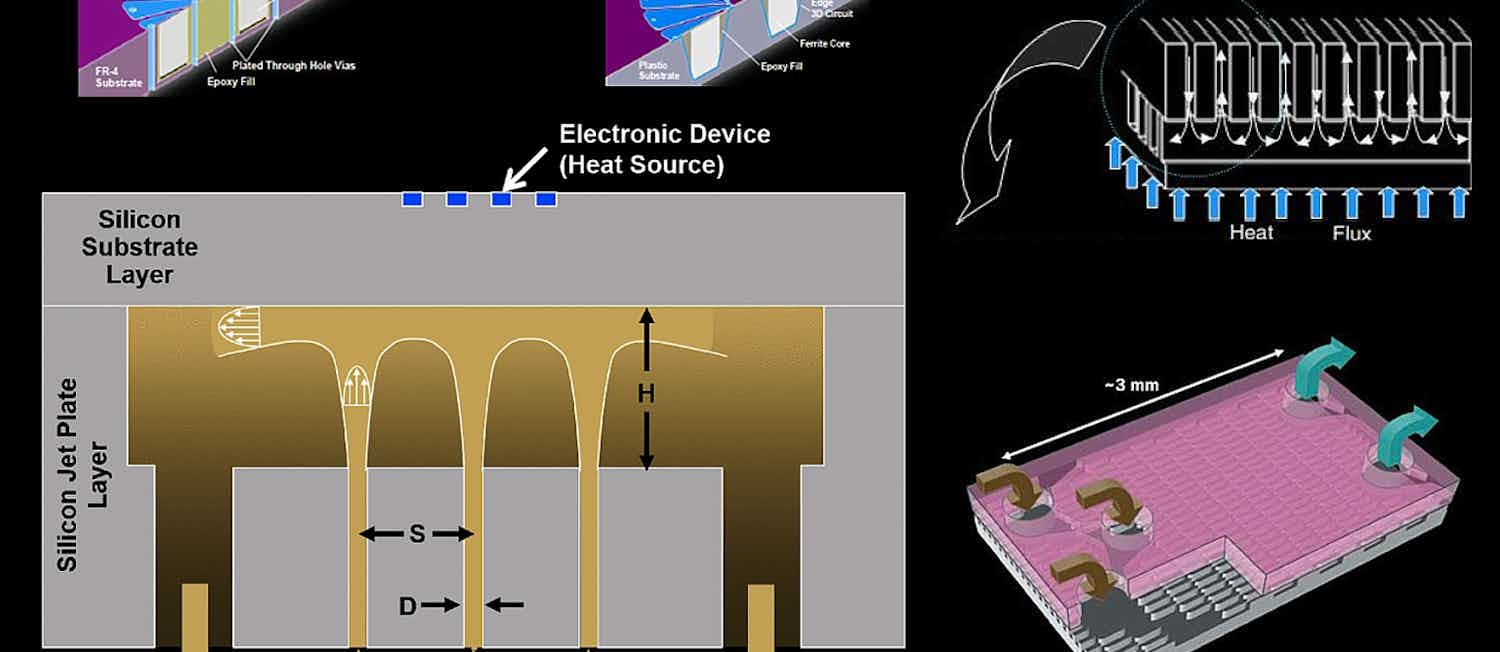

Plated through hole (PTH) and blind via (BV) are two technologies that make it possible to嵌入(图1)。

Reliability of 3D Integrated Power Packaging

增加电力电子设计中的功率密度需要更好的冷却技术前进,例如集成冷却。控制功率分量的温度至关重要,对设备可靠性和性能至关重要。然而,电力电子系统的创新热管理是电力致密化的关键瓶颈。

Wirebond/Solder Die Attach vs. Sintered Interconnects

For optimum power-density reliability, traditional wirebond techniques need to move toward sintered interconnects, which would eliminate wirebond failures.

Silver sintered power devices are an alternative interconnect technology to standard solders. The technology is different from other interconnect technologies due to improved thermal and mechanical properties. A high fatigue life is achieved in testing when compared to standard solder die attach and Al wire top contacts.

嵌入式组件

电容器

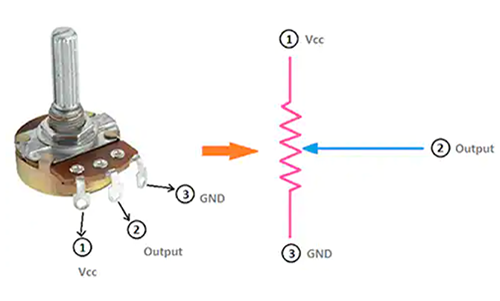

There are two methods of embedding capacitors into 3D structures:

- 嵌入式电容膜

- Embedded capacitor devices

Inductors

有两种方法将电感器嵌入到3D结构中:

- 平面磁性

- Deposited inductors

Cooling Methods in 3D Power Packaging

嵌入式歧管 - 微通道冷却器

These types of coolers can be embedded directly into the substrate or chip and will provide localized heat removal at high volumetric rates from the backside of active integrated circuits and power electronic devices(Fig. 2)。它们可以以多种形式使用;例如,单相,硅与陶瓷基板和不同合金,过滤尺寸,工作流体,流体速度和温度。

Force-fed two-phase manifold cooler

A series of parallel microchannels can have perpendicularly oriented manifold to distribute flow(Fig. 3)。微沟表面在单晶硅碳化硅(SiC)中制造。

足够的电力装置彼此热隔离

3D集成电力电子器件将使用新的包装技术。这些冷却方法的可靠性仍然被理解和建模。

Fluid immersion cooling

Immersion cooling has risen as a solution to overcome barriers, such as single-phase cooling, by a method of boiling a cooling fluid directly from the electronic components. This will help remove the need for most thermal interface materials and packaging constraints found in many other approaches.

State-of-the-art immersion-cooling systems employ dielectric heat-transfer liquids due to electrical considerations. This presents fundamental disadvantages related to the relatively low boiling point, low critical heat flux (< 20 W/cm2), and relatively poor thermophysical properties (e.g., thermal conductivity, latent heat, surface tension) when compared to higher performance fluids such as water. However, compromises need to be considered since water can damage electronics systems. Check out “The Best Heat Transfer Fluids for Liquid Cooling (boydcorp.com)” for viable heat-transfer fluid options.

微射精冲击的高热传递

Improving the power density of advanced electronics, and in particular gallium-nitride (GaN) high electron mobility transistors (HEMTs) in RF power amplifiers, represents a big challenge in thermal management. High-heat-transfer capability of microjet impingement can be employed to bring cooling directly to the backside of the power electronic device(Fig. 4)。

High-power-density electronics device cooling loop using a liquid-metal coolant

This method employs the use of liquid gallium alloys, which have a thermal conductivity (approx. 28W/m/K) that’s 40 times greater than the thermal conductivity of water.

概括

This article has suggested some very powerful methods that designers can employ to increase power density in 3D packaging. For instance, embedding and integrating was mentioned as a good way to improve power density. Various cooling methods also were discussed as ways to boost power density. Which method is best suited for your 3D-packaging design?

参考

1.Reliability of 3D Integrated Power Packaging (psma.com)

2.”Embedded Microjets for Thermal Management of High Power-Density Electronic Devices,”IEEE Journals & Magazine

3. Study and realization of a high power density electronics device cooling loop using a liquid metal coolant, Grenoble Electrical Engineering Laboratory (G2Elab)