|

|

以.pdf格式下载本文 This file type includes high resolution graphics and schematics when applicable. |

A most critical device in an optical networking system is the laser diode, since it’s responsible for converting the electronic data to light pulses. This diode must be carefully controlled to stabilize the light output, and temperature is a key variable to determine the light’s wavelength. Thermoelectric coolers (TECs) are commonly used as part of this stabilization process. Since TECs come in many different power levels and have unique power requirements, a specific type of power supply is required to drive them properly.

一个侦探anot转移热能从一个盘子her to make the first plate cooler or warmer. A TEC doesn’t consume energy itself; in other words, no energy is lost, but energy is required to operate the TEC. A TEC is modeled as a simple resistor that can withstand a certain voltage across it and current through it. This power corresponds to a maximum temperature difference between the two plates for a given TEC. The higher the power applied, the higher the temperature difference between the plates.

TEC的一个重要方面是它们具有加热和冷却的能力。由于TEC永久安装或连接到需要温度调节的激光器或其他设备上,因此只有一个板块控制激光的温度。另一个板必须安装到散热器上,以释放从第一盘移动的能量。这两个板都需要非常好的热连接才能达到最佳系统性能。

一旦安装在系统中,板就无法逆转。TEC必须支持给定方向的冷却和加热。TEC通过控制电流流的方向来支持此互补功能。朝着一个方向流动的电流会冷却一个板并加热另一个板,而电流沿反向方向流动会逆转此动作,加热第一板并冷却第二板。结果是与仅在一个方向上流动的电流相比,温度控制范围更大。

Since TECs require bidirectional current flow to achieve the desired performance, their power supply must support this dual mode as well. However, many power supplies can only source current. Therefore, a special circuit needs to be designed to swap the connections from the power supply to the TEC when cooling is needed versus heating, which complicates implementation of the supply.

另一种方法是设计一种可以通过与TEC进行不变的连接来源和下沉电流的电源,从而满足当前流量的要求。但是,只有一些电力供应设计支持采购和下沉电流。此外,供应必须支持零电流值接近的操作,这是一个常见的工作点。

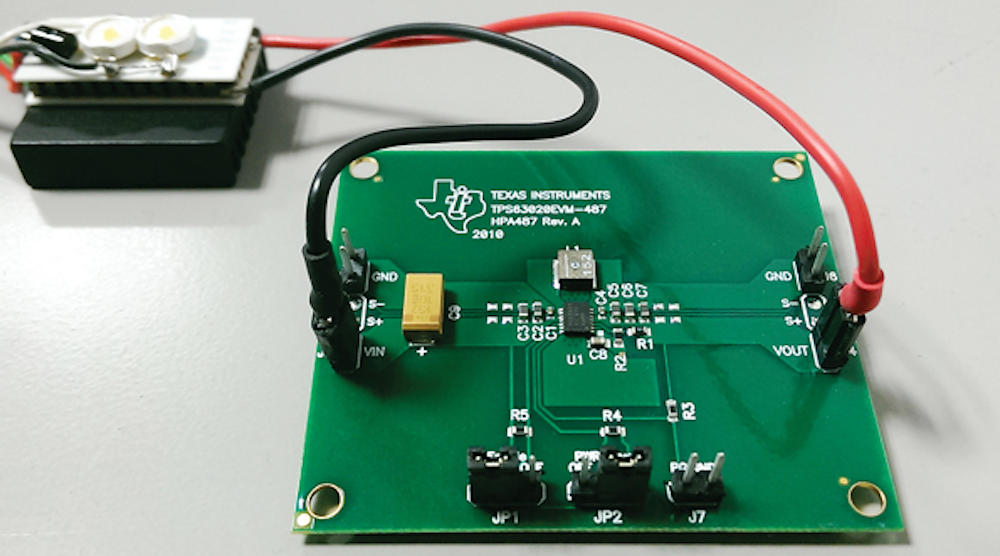

图1中的功率供应是可以为低功率TEC源和下沉电流的电路。例如,诸如TPS63020之类的降压转换器用于降压或增强所提供的输入电压,以生成所需的电流流动方向。降压转换器的拓扑支持宽的输出电压范围,在这种情况下,从1.2到5.5V。

By integrating all power MOSFETs and requiring a minimum of external components, this circuit is a more preferred approach for low-power TECs where size is critical, such as in the smallest optical-networking modules. The buck-boost converter is powered from the common 3.3-V rail found in optical networking modules. The TEC’s connections to the power supply(图2)在TEC上允许 +2.1至–2.2-V电压差。此外,在此配置中很容易支持零电流附近的常见工作点。

TEC取向对其加热或冷却至关重要。现代电子产品通常似乎有些温暖且易于进一步加热。但是,通常很难冷却到足以达到所需的激光波长。因此,最好将TEC接线,以便当降压转换器采购电流时正在冷却。TPS63020与许多源和下沉的转换器一样,可以采购比下沉更多的电流。因此,下沉时它可以传递较小的功率,因此应使用下沉电流来加热TEC。

在完整的系统中(图3), a microcontroller (MCU) monitors a temperature sensor on the TEC. Based on the TEC’s actual-versus-desired temperature (the setpoint), the MCU adjusts the control signal (VCtrl) to move the buck-boost converter to a new operating point, sourcing or sinking more or less current to adjust the temperature.

References: