Power distribution in data centers used to emulate the architecture of old telephone central offices. A “rectifier” would step down and rectify the ac from the power line and use it to charge banks of batteries that provided an unregulated 48 V dc, which was distributed around the facility to run the telephone equipment in the racks.

Since at least 2007, data-center engineers have been talking about distributing 400 V dc (sometimes 380 V). Data centers are bigger and use a lot more power than telco central offices. At a minimum, higher voltage distribution would mean lower I2r损耗和/或功率分配电缆更薄。

|

|

Download this article in .PDF format This file type includes high resolution graphics and schematics when applicable. |

As data centers have grown in size and as cloud computing looks more and more economically viable, the use of 400 V has started to gain traction. In addition, one semiconductor company has released the missing silicon link in the chain. There is now a 400- to 12-V switching buck regulator device with efficiencies in the high 90s.

Power In The Data Center

As the use of the cloud for data storage grew in the early years of the 21st世纪,电力相关的两个问题erged. One was the sheer power drain in kilowatt hours associated with a data center, not just for the transaction processing alone, but also for dealing with the waste heat generated by rows and rows of cabinets housing dozens of blade servers. The other was the incredibly rapid di/dt demands of the blade processors in those servers as their cores shifted among operating states.

用于核心,外围设备和每个处理器中的存储器的高压电压轨可能在类似于Volt的内容上运行。然而,由于处理器改变操作状态,因此在面对当前需求的当前需求的变化时必须紧密调节。

Power sourcing led to the siting of new data centers close to power generating facilities, which cut the cost of delivered power. Inside the data center, the issue was power distribution: how to get it from the utility drop to the ICs inside each blade server. The generally accepted solution was the Intermediate Bus Architecture (IBA). An IBA implementation has three stages:

•设备机架中的前端供应下降,将电源电压从电力公司的AC电源电压整流为半规定的48 V DC。它将电路板和电路分离在AC电源的致命特征下游下游。

•系统中的每个板都有自己的降压电源或总线转换器,可将前端的48 V至12-,8 - 或5 V总线电压变为。实际电压是降压调节器在负载点(POL)和总线IR下降和I的效率之间的权衡2R losses.

•总线电压下降,由位于每个负载的负载点(POL)转换器的非隔离降压转换器升压。

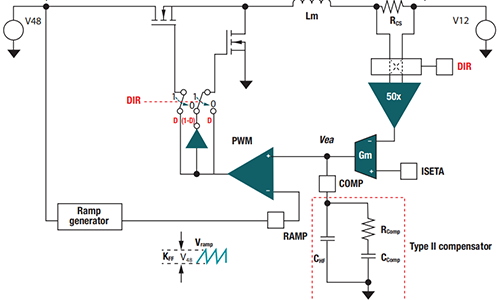

Most IC companies adopted IBA. Vicor created a different approach that it called Factorized Power. Vicor intended Factorized Power for a wider range of applications than data centers, but the data center was a candidate from the beginning. The approach is based on very efficient non-regulating, isolated POL-like chips at the load while moving the regulation function upstream.

分解权介绍了自己的术语。隔离电压变换模块(VTM)位于负载。上游,预制器模块(PRMS)基于VTM的反馈提供实际调节。PRM调整分解总线电压以保持调节中的负载电压。

VTMs function as current transformers. They multiply the current (or divide the voltage) by a “K” factor. This takes place with essentially a 100% transformation duty cycle, so there’s no loss of efficiency at high values of K. Thus, the bus voltage can be (and is) greater than 12 V. PRMs can operate with input voltages from 1.5 to 400 V and step up or step down over a 5:1 range, with a conversion efficiency up to 98%.

Despite its design elegance, sole-sourced Factorized Power never displaced IBA, which was supported by many competing IC companies whose products were priced competitively.

Many engineers, includingElectronic Design’s emeritus editor in chief Joe Desposito, argued that swapping 48 V dc, a separated or safety extra-low voltage (SELV) according to international standards bodies, for 400 V dc, capable of pushing a lot of current, was never going to be popular. Actually, it’s coming faster than you think.

What’s interesting is the thinking behind it, the equipment that’s already available, and the fact that Vicor has just released a regulator device that works with its Factorized Power V-chips to handle what’s been a “missing link.” It’s a high-current 400- to 48-V dc step-down device in s small package.

400-V History

The document most often cited with respect to 400-V dc distribution in data centers was presented at the 29th International Telecommunications Energy Conference (INTELLEC) in 2007:400V直流分布在电信带和数据中心提高能源效率的评价by Annabelle Pratt, Pavan Kumar and Tomm V. Aldridge. Most of the chips in those blade servers were Intel’s, and regulating the voltages for the power rails on those chips had been the driver for distributed power architectures.

2010年,英特尔发布有点短的白色paper based on the conference paper: “Evaluating 400V Direct-Current for Data Centers,” with the subtitle:“A case study comparing 400 Vdc with 480-208 Vac power distribution for energy efficiency and other benefits,”by the same authors, plus Dwight Dupy and Guy AlLee.

The 2010 paper described an in-depth case study conducted by Intel in conjunction with EYP Mission Critical Facilities, which is now an HP Company, and Emerson Network Power for a 5.5-MW data center. The study concluded that energy savings of approximately 7% to 8% could be achieved over high-efficiency, best-practice 208 to 480 V ac with a 15% electrical facility capital cost savings, 33% space savings, and 200% reliability improvement.

According to Intel, 255 to 375 W is required at the input to the data center to deliver 100 W to the electronic loads. Anywhere from 50 to 150 W is used for cooling. About 50% of the power that’s left is lost in front ends, power distribution units and cabling, power supply units, voltage regulators, and the server fans used inside the cabinets that hold the blade servers. Better efficiency is possible with 400-V dc power delivery because it eliminates three power conversion steps and enables single end-to-end voltage throughout the data center.

Why 400 V In Particular?

Previous studies also have identified 400-V dc power distribution as the most efficient. According to the 2007 IEEE paper, 15 different nominal voltages have been proposed, and Intel recognizes the need for flexibility. Nevertheless, having said that, 400 V dc does offer some particular advantages.

No phase balancing is required, which reduces the complexity of power strips and wiring. No synchronization is required to parallel multiple sources. There are no harmonic currents to worry about, eliminating the need for power factor correction (PFC) circuits. It can use fewer breakers (up to 50 percent for this case study) because of fewer power conversion stages. And, it simplifies wiring since only two conductors are required.

Also, a link voltage of approximately 400 V dc already exists in today’s ac power supplies, as well as in the bus in light ballasts and adjustable speed drives (ASDs) that often are used to power fans and pumps in the data center. Because 400 V dc builds on the existing components in high-volume production server and desktop power supplies, the lowest power supply cost is ensured by not increasing the voltage any higher.

不间断电源(UPS)系统通常使用540 V DC的更高电压直流总线,这很容易重新设计以支持400 V DC。此外,每个IEC 60905-1电源标准的间距要求对于通用输入(90至264 V AC)电源和用于低于420 V DC的工作电压的直流电源也是相同的。这是有利的,因为它允许重复使用AC电源存在的高批量设计。

此外,400 V在现有的600V安全极限内很好。它通过标准的600V额定布线和母线系统运行。商业解决方案已经出现了。最后,连接可再生能源(如具有可变频率发生器)的可再生能源更简单和更有效,因为它们还具有在该范围内的电压下具有更高电压的直流总线。

The Analysis

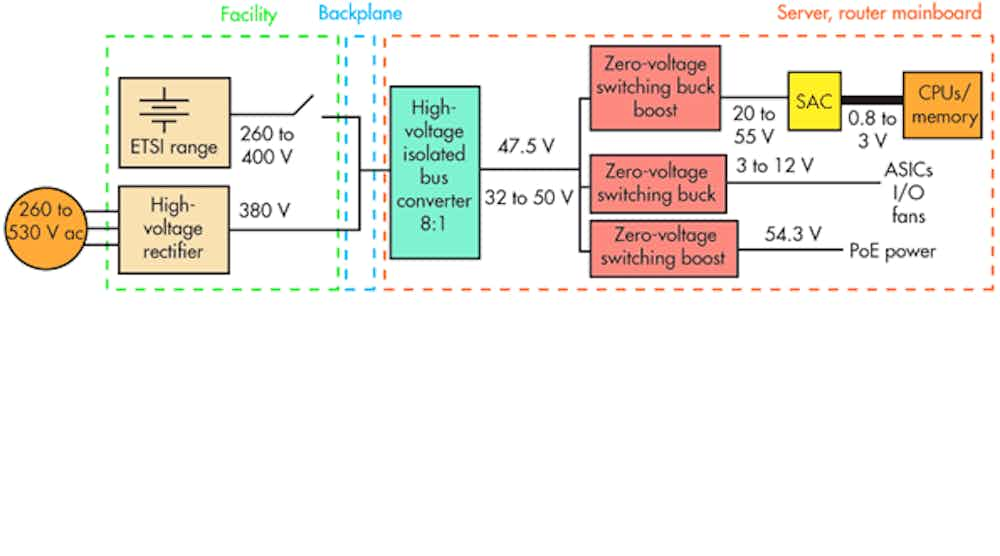

That’s the theory. Here’s what happened. Researchers from Intel, Emerson Network Power, and EYP Mission Critical Facilities, a data-center design services firm that was later acquired by HP, applied the 400-V dc model to an extension of an existing data center to add three additional modules. The details are in the original paper and the white paper. The exercise was to compare a 480-V ac design with a 400-V dc design(Fig. 1).

在传统的交流方法中,中央占据构成前端。输入电源已纠正并馈送备份存储系统。然后将DC反转回AC并发送到分配单元,其中电压逐步下降到208或120 V,其分布到服务器机柜。

A power supply in each server re-rectifies the 208 V ac to a dc voltage between 380 and 410 V dc, which is subsequently buck-converted down to 12 V dc. This voltage then is routed directly to the hard drives, which are not fussy about regulation. It is regulated down for the ICs in each server as well.

The Intel analysis also included a dc-dc converter between the battery and 400-V dc distribution bus, but it noted that the batteries can be connected directly to the bus. The analysis also showed that the equipment for a dc data center would require only about two-thirds the space of an ac facility, freeing up more room for servers.

When the two alternatives were modeled, the researchers obtained the results noted above. Specifically, the dc approach produced a 7.7% energy savings with a 50% load and 6.6% savings at an 80% load. In dollars saved per year, that’s $150,000 for a 5.5-MW data center operating at 50% load. (That was the calculation for the conditions prevailing in 2007.)

在可靠性方面,计算显示两个fold improvement in availability over five years, with a calculated probability of failure of 6.72% for the dc distribution versus 13.63% for ac distribution. (Those are the numbers from a standard reliability calculation.)

Safety

Whether it’s ac or dc, 400 V will hurt. Placing yourself across 400 V pushing hundreds of amps won’t leave a whole lot to bury. Yet ac or dc, 400 V is what we already have in data centers. “Current data centers with conventional UPS systems, which contain batteries as their backup energy source, are operating with dc bus voltages at the UPS at about 540 V dc,” Intel said in its white paper.

“操作和维护人员目前熟悉这些级别的电压,并且使用400V DC系统的使用并不比目前使用的更危险。众所周知,使用更高的AC或DC电压在数据中心机架和机柜内部可以将数据中心人员暴露于它们通常不熟悉的电压,“它继续。

然而,在美国,在50 V上方的任何标称电压都被认为是危险的人员,并且当一个人使用或使用比这更高的电压时,相同的预防措施和个人防护设备是强制性的,“它结束了。

数据中心设计更新

Unfortunately, the Intel study is from the 2007-2008 timeframe. Data-center design has been evolving, but more in terms of server design than in power distribution. (See:“一世ndustry Experts Assess Power’s Frontiers,“)

TheIEC 61850standard, which came out after the Intel documents, deals with the design of automated electrical substations. It’s part of the IEC Technical Committee 57’s reference architecture for electric power systems.

标准的抽象数据模型可以映射到使用高速切换以太网的TCP / IP网络和变电站本地区域网络(LAN)运行的各种数据协议。部分地,它是关于使许多配电元件讨论在内容互联网上面。

A new model for data centers replaces the old model of aisles and aisles of cabinet racks filled with blade servers sitting on raised computer floors and cooled by internal fans pushing cooled room air produced by rooftop air conditioners. It recognizes that the average cell phone boasts approximately the memory capacity and processing power of an old-fashioned blade server.

Moreover, lacking a disc drive, the cell-phone-style server is perfectly happy at elevated temperatures. Consequently, new data centers can operate “in the dark” like modern semiconductor fabs, with much denser arrays of servers, operating in closed cabinets whose internal temperatures can be allowed to rise to much higher temperatures than would be comfortable for human workers, while the external environment is maintained at temperatures that are suitable for only occasional visits from real people. That doesn’t change the economics of distributing power via 400-V dc, but it does make some of the construction simpler.

Found: The Missing Link

1月,Vicor宣布前400-V DC到48-V DC(名义)总线转换器模块以使用其芯片(“封装中的”转换器“)模块技术。BCM380Y475X1K2A30的直流输入范围为262至410 V DC。其标称输出电压为47.5 V DC,但可以为32.5到51.25 V的任何输出素材设置。

Rated for 1200 W, the module can handle up to 1500 W peak. In OEM quantities, unit pricing is $120. Dimensionally, it’s roughly 2.5 inches long, an inch wide, and something less than a third of an inch tall(图2)。The key to its size and power handling capability is the CHiP package technology, introduced at last year’s APEC conference. (See:New Thermal Design Options Drive Power Density。)

Efficiency is remarkable, peaking at 98% and remaining in the mid-90s down to 10% of rated load(Fig. 3).

The BCM is designed to be used with Vicor’s other V-Chip devices. In other words, it provides a step-down stage that’s followed by the more familiar upstream regulation controlled by the current transformer at the point of load(Fig. 4).Beyond that, the company provides instructional videos, an evaluation board (BCD380x475x1K2A30), and graphic design tools.