While upgrading the grid and repowering the data center are grand, sweeping issues, it’s important not to lose sight of basics. For an international perspective, we discussed future efficiency gains and advances in digital power with senior executives at European power supply companies: Jeff Schnabel, VP of marketing at CUI Inc.; Don Knowles, VP of engineering at N2Power; and Gary Bocock, technical director at XP Power.

Don Tuite交直流恋爱补给品:中等大小的效率es is now firmly in the mid-90% area. And while these efficiencies are impressive, the vast number of power supplies shipped each year means even small efficiency gains have a significant effect on our power consumption. Where do manufacturers go from here, and what limitations are in place?

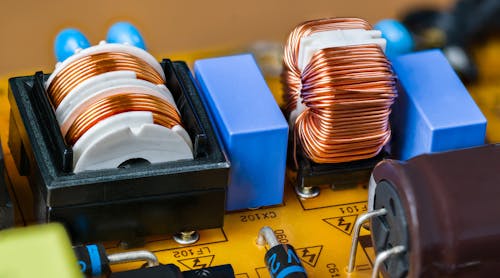

唐·诺尔斯:我们看到四个基本领域的潜在增长:互连,及其寄生性和电感,以及电感器中的铜和能量损失;功率组件和拓扑;选择半导体,例如增强模式二氮化甲基二氮FET和SIC(硅)二极管;和更好的磁性组件,具有较低的核心材料。

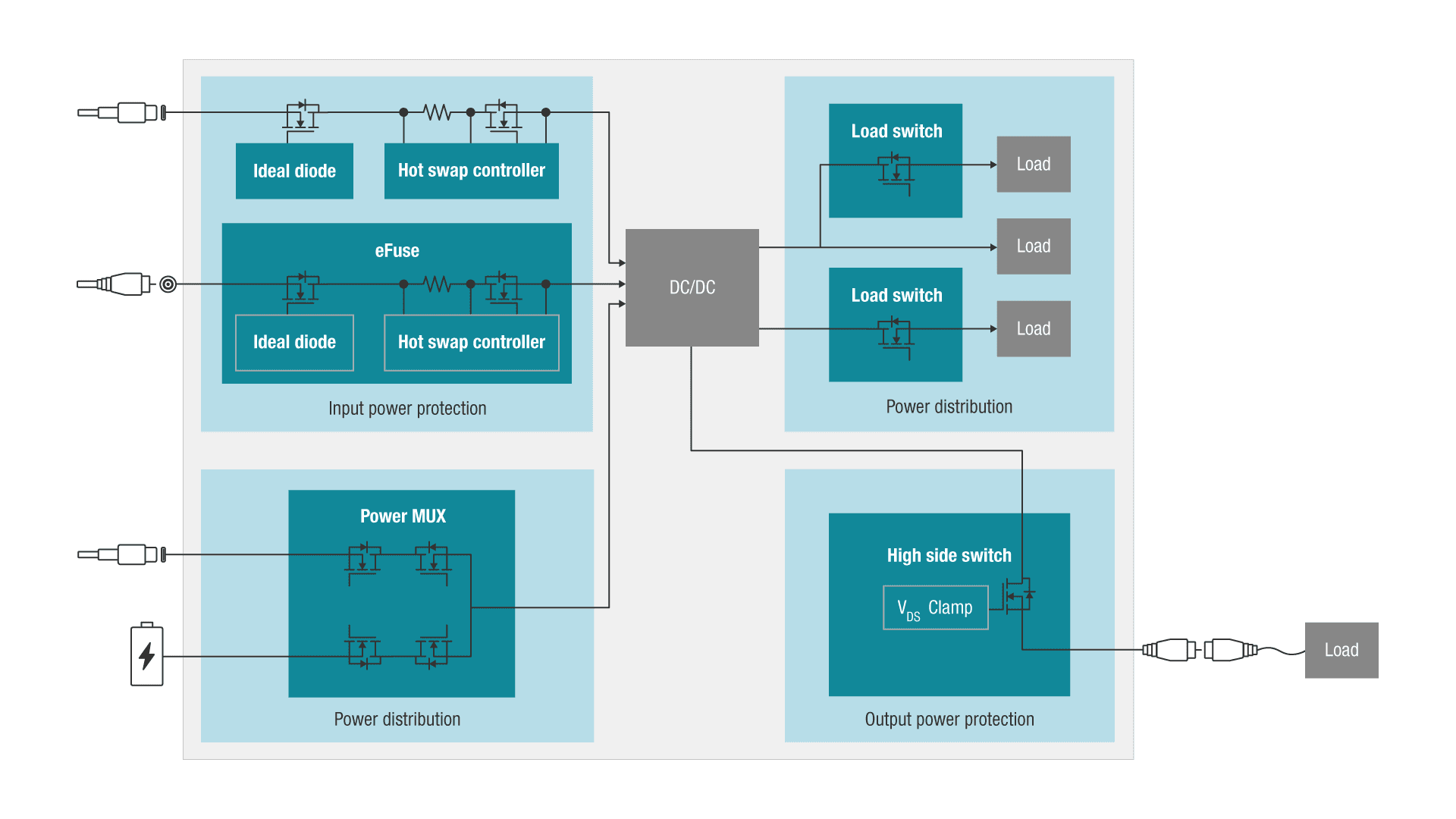

Gary Bocock: In many ac-dc power supplies, the bridge rectifier generates the biggest single power loss. This is a low-cost, low-technology, reliable component, and replacing it with a more efficient solution is more complex and expensive. There are products that use bridgeless PFC (power factor correction) designs, though this tends to be limited to higher-power, higher-cost products. Higher-power products also utilize interleaved PFC designs, significantly reducing the losses at low line input and reducing stress on the bulk storage capacitors.

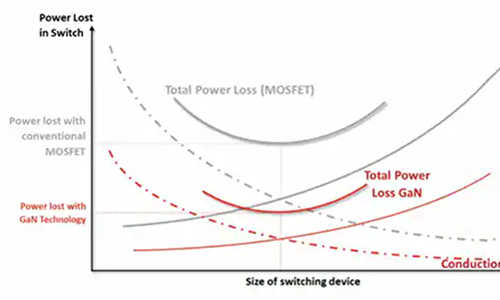

杰夫·施纳贝尔(Jeff Schnabel):我相信,明天的创新将通过发现和实施新的电力拓扑和材料,例如硝酸盐(GAN)和碳化硅。例如,与常规的雄鹿转换器相比,CUI的[DC-DC] Solus Power Topology当前能够将切换转交损失减少75%,而对照FET的关闭损失则减少了99%。我们的测试表明,在AC-DC中实施时,它具有相似的优势,最终允许提高效率并减少包装大小。

DT:我们在2013年会看到多少改进,五年来可能有什么?

JS: We see that the biggest short-term gains in power supply efficiency, overall, rather than peak, will come as a result of reducing power consumption at the no-load end of the curve, i.e., when the device is in standby. We’re not alone, however, and the regulation bodies have begun to make this a priority. Along with the introduction of new topologies, digital control in ac-dc supplies will also have a significant effect over the next five years, allowing for greater power supply and power system optimization.

DK:我们将在2013年的效率上增加一到两个百分点,在未来五年内提高2到三分,以及在更广泛的AC线输入范围内的功率因数校正性能的提高。也许最明显的是,数字控制循环的使用增加(不仅仅是模拟循环的数字监督)会改变性能水平,提高PFC,增加灵活性,使供应能够适应变化和复杂的线路和负载情况,并提供更高的实地现实 -time reporting on the supply’s operation and internal parameters.

GB: The latest designs include quasi-resonant PFC stages, resonant power converters, and synchronous rectification to minimize the switching and other losses throughout the power chain. New products reach efficiencies of 95% at high line input voltages and maintain efficiencies above 92% at minimum input voltage. The development of components and techniques will see this improve.

DT:通过电源提高系统效率面临的最大挑战是什么?

GB:重要的是要专注于低线效率和成本效益的方法,以减少整流和功率因数校正阶段中的功率耗散。市场价格仍然是关键的推动力,尤其是对于低功率产品,因为效率较小的成本可能令人难以置信。继续减少产品的尺寸对提高效率和产品寿命会产生不利影响。

JS:最大的挑战在于切换转换的基本性质以及转交和关闭时相关的切换损失。电源设计师的永无止境的挑战将是通过拓扑突破或组件级别的改进来最大程度地减少这些损失。

DK:当前水平正在增加,因此接触和铅阻力,内部IR下降和相关基础知识变得越来越严重。以更高的内部电压操作供应是提高效率的答案的一部分,但这带来了新的蠕变,间距和安全问题。由于磁性核心损失增加并增加了半导体的开关损失,增加操作频率将降低尺寸但不能降低效率。

DT: What are the key factors OEMs should specify if they are to improve the system efficiency through the power supply?

DK: First, don’t oversize the supply for insurance headroom. If you run the supply at much lower loads than this zone, you’ll actually be operating in a very inefficient region. Second, try to avoid active (forced air) convection cooling using fans since they waste power, add noise, and reduce reliability. Instead, use an efficient supply, properly sized, and mount it so unforced convection and conduction cooling will keep it within its rated temperature.

GB: The key is to look at power supply efficiency in the operational area of use, i.e., look for the detail rather than the headlines. If the equipment will be used throughout the global market, then the efficiency at low line is more interesting that the headline efficiency at 230 V ac. The load drawn in the application is important as products often offer their peak efficiency at higher percentage loads. There is a tradeoff between efficiency, size, and cost, which drives the product design.

JS:由于现实世界系统通常不处于稳定状态,因此OEM应检查电源的完整效率曲线,并确保其对其应用程序的负载配置文件进行优化。通过这样做,他们可以最好地将电源与系统需求相匹配。