When electrons flow through a resistive material, heat is generated. It’s not uncommon for high-power IC chips to dissipate greater than 50 to 100 W. A few years back, projections showed that chips would commonly reach 400 W or more. This increase in IC power levels has taken a back seat as energy conservation efforts have accelerated, as desktop computing has given way to battery-powered systems, and as cell phones and tablets strive for ever longer battery life.

As a result, power consumption growth rates have slowed and even reversed in some instances. At the same time, packages are shrinking to meet the needs of portable and space-constrained systems. Power densities can still be high, greater than 10 W/cm2,即使总功率降低了。如果没有从死亡中进行热量,则与伴随的电故障发生过热。

热设计的系统首次打开时通常可以工作。但是,当它们加热并达到临界温度时,它们会锁定。关闭并允许冷却后,他们再次工作。这种行为“指纹”指出了潜在的热强设计。涵盖各种笔记本电脑,电源和智能手机的博客曾经充满了抱怨产品过热的最终用户。两种趋势正在解决这些问题:自感应电子设备,当它们开始过度过热和专业知识以优化热性能时,这些电子设备的性能和动力消耗。

结构的作用

模具结构本身对于热性能至关重要。在一个位置中,大量功率耗散电路元素会产生可能难以冷却的热点。导电硅可以帮助抵消此问题。例如,更厚的模具更有效地将热量从功率致密区域远离,从而改善了热点冷却。另一方面,将模具变薄会增加传播的热电阻。模具上的金属化可以帮助从这些热点进行热量,具体取决于其几何形状和金属布局,从而降低温度。或者,模具上介电的类型和厚度会阻碍热传导,从而导致死亡加热。

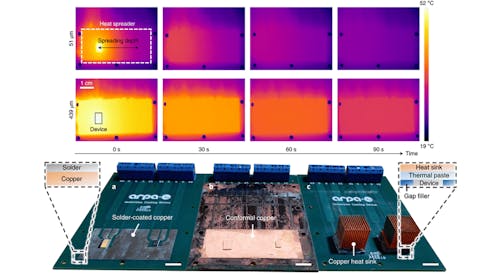

接触模具的每个结构都成为模具热量的热导通路。触摸模具的一切都是散热器。在包装中,模具附加材料从模具中的材料导致铅框架模具垫或基材中的铜平面。霉菌化合物从模具和模具垫的表面进行热量,以指导手指或包装表面(Fig. 1)。如图所示,电线键和底物痕迹可以将热量进行加热,以将热量传递到印刷电路板(PCB)中,该球的作用像是包装的散热器。

1. An over-molded, wire-bonded IC package attached to a system-level PCB can take advantage of common thermal conduction paths (shown in red) for cooling.

The heat-spreading efficiency of a package primarily depends on the layout of the metal structures within it. Why? Copper’s thermal conductivity is 386 W/m-°C at room temperature. Solder conductivities range from 30 to 60 W/m-°C depending on the alloy implemented. Compare this to insulating polymer conductivities of 0.1 to 2 W/m-°C, depending on the filler material. The polymers are two or more orders of magnitude less thermally conductive than the copper. Metal in the package and the system board and chassis will conduct most of the heat.

The design of the metal must be carefully controlled for thermal management. To keep the chips cool, high thermally conductive metal paths must be implemented to spread the heat for improved convection and radiation into the system environment. Each package type will have its own set of thermal paths that require optimization.

设计人员应使用通用的热路径用于电线固定的铅框套件和Flip-Chip基板套件,但它们通常不是(请参阅表)。例如,由于过程复杂性,成本以及有时的可靠性风险,很少会将引脚连接到铅框套件的垫子。包装设计人员有责任了解每个软件包的特殊配置,并评估需要优化的重要热路径。

系统观点对于包装热增强至关重要。例如,如果预期进行散热,则必须优化从模具到散热器安装表面的热传导。需要努力使这条路径尽可能传导。如果要将PCB用作散热器,则需要在包装中(或暴露的热垫中的热量)进行热传导路径,以在PCB中的热扩散特征中(Fig. 2)。

2. This four-layer PCB cross section shows a package with an exposed pad soldered to a thermal landing that is connected to the PCB ground plane through thermal vias. The vias are isolated from the power plane for electrical reasons. In this figure, the ground plane would become the thermal spreading plane assuming it was continuous over a large area

PCB必须有足够的spreading area on each device to convect and radiate the required heat load(Fig. 3)。

3.连接到IC包装的热播放平面的面积决定了PCB的冷却效率。有效的qja在包装下的(x,y)长度的函数的12毫米12毫米芯片尺度的包装中,绘制了该封装下平面的(x,y)长度的函数,最多可达104 x 104 mm。假定两个痕量长度,显示了从痕迹进入平面的热量偶联。

此外,设计师必须了解板是否会被风扇,通风的围墙或甚至通过董事会在重力方面的方向进行空气。在风险分析期间应预期意外后果。例如,如果系统通过插槽被动冷却,那么当最终用户将外套悬挂在上面或灰尘积聚时会发生什么?设计中是否有利润来确保在不利条件下进行良好的操作?

最佳实践

为了取得成功,优秀的热力工程师将在其设计实践中纳入六个步骤:

• Determine the power that will be dissipated under all use conditions.

• Ensure all design inputs such as thermal properties are accurate.

• Identify the range of thermal enhancements that fit the application space and system cost targets.

•通过建模迭代以找到多个设计解决方案。

•与共同设计团队共享解决方案,并接受反馈。

• Validate the modeling predictions to improve the process for future designs.

热设计工程师还必须避免常见的陷阱。例如,他们不得专注于以牺牲他人为代价的一条热路径。作为洗衣清单,如果PCB的设计不足以扩散热量或已经将过多的热量倾倒到PCB中,则将从芯片改为PCB的热传导将不会产生太大影响。

改善气流可能无法修复即使是最具侵略性的气流速度也没有足够的热点的系统。在没有气流的系统区域中放置有效的散热器不会导致太大的热增强。如果系统电缆阻断气流,则散热器将变得无效。在系统PCB中涂抹迹线以使建模任务更容易,可以将隔离的隔离封在金属平面中,以阻止热量传导。必须考虑所有环境条件。例如,室外操作期间的阳光比电子产品生成的能力更多。

Software tools are a must for thermal enhancement and optimization. Thermal engineers should be intimately familiar with their tool of choice, knowing its strengths and weaknesses. Factors such as convergence, mesh sensitivity, and mesh simplification must be addressed to ensure accuracy.

系统热分析中最大的误差来源通常是系统消散的功率的估计。对于可编程的系统,功率耗散是软件和功能的函数,尤其如此。例如,平板电脑上的视频编辑使用与游戏玩法或书本阅读不同的指令集。一件软件上的网页渲染比另一个软件的网页渲染更大。常见的做法是在最常规使用水平上设计系统,同时在高功率操作推向热过热时,使热替代效力以防风系统。

即使设备功率降低,复杂性和小型化的增加也在推动热管理要求。设计学科对于消除系统中的过热至关重要,并以最低的成本提供最佳的热溶液。复杂的系统必须在预定的寿命中可靠地运行。通过对热增强选项,模具系统共同设计和热风险分析的预先了解,可以克服热问题。

Darvin Edwards, TI Fellow, manages the SC Packaging modeling team at Texas Instruments. His team is responsible for electrical, thermal, and thermomechanical analysis of new products and package developments. He received his BS in physics from Arizona State University and holds 20 patents. He also has authored or co-authored over 45 papers, articles, and book chapters and has lectured on thermal challenges, modeling, reliability, electrostatic discharge (ESD), and 3D packaging.