It’s not easy being a brushed dc motor these days. Although this is the oldest dc-motor configuration, in recent decades it seems that brushless dc and stepper motors have been getting most of the attention and glamour. This deserved position is largely due to their unique performance attributes and controllability, which is mostly the result of improved switching devices supported by microcontroller-based management via efficient algorithms. In contrast, some designers may think of the brushed motor as a hard-to-control, unreliable, electrically noisy relic (those brushes!) of the past.

然而,现实情况是,刷直流电机is a cost-effective solution for a wide range of applications, such as line or battery-powered 12- to 36-V industrial devices, home appliances such as coffee machines and robotic vacuum cleaners, ticket/receipt printers, medical devices such as infusion pumps, and electronic door locks that require a high-current impulse-like drive. When coupled with an enhanced driver that maximizes their basic functionality, they are a viable prime mover for these and other applications.

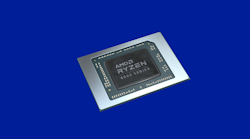

To meet this need,Toshiba Electronicshas added a new brushed-motor driver to its portfolio of single-channel dc motor-driver ICs(see figure). The TB67H451FNG, in a small HSOP8 package measuring just 4.9 × 6.0 mm, is a PWM chopper-type driver that supports both PWM constant-current drive and direct PWM drive. It has four operational modes: Forward, Reverse, Brake, and Stop (Off).

The driver operates from a 4.5- to 44-V supply and thus supports applications down to those with a 5-V USB supply. Maximum motor-drive output current is 3 A at 44 V. The internal output-MOSFET path has a low on-resistance for the high side plus low side of 0.6 Ω (typical).

A good motor driver comes with protection, recognizing that faults are part of the reality of motor applications. Among the protection mechanisms built into the TB67H451FNG are undervoltage lockout (UVLO), auto-return thermal shut-down, and non-latching overcurrent protection (OCP). Note that Toshiba’s existing driver, the TB67H450FNG, features a latching overcurrent detection that turns the output off indefinitely until power cycles or its circuit enters and leaves standby mode. In contrast, the this new TB67H451FNG IC is non-latching and resumes function automatically after a programmable recovery time, once the overcurrent condition is removed.

Toshiba has also optimized the TB67H451FNG standby-current consumption by incorporating a supply circuit that meets requirements for lower-power consumption. It does this by, among other techniques, enabling automatic transitions from STOP mode moving to STANDBY mode and turning off the VCCregulator of the internal circuit. The detailedTB67H451FNG datasheetincludes both timing diagrams for the various operating modes as well as circuit diagrams showing the four different current paths through the output MOSFETs that are set by the user via two control lines.

Reference

Sunil Kedia,Machine Design, “Controlling Brushed DC Motors Using PWM”