Download this article as a .PDF

The future has arrived in the form of medical wearable devices. These devices are often comprised of a ridged box of electronics with a battery and some type of adhesive, so that it can attach to the patient’s skin. This close contact can be a problem when you consider that some wearables stay on for long periods of time. Comfort is incredibly important, as anyone who wears a prosthesis could tell you. And trying to mount a stiff silicon chip and hard-bodied battery on a ductile human body, isn’t necessarily comfortable.

那么,我们如何在舒适的包装中提供PCB,芯片,传感器和电源呢?西北大学机械工程,土木和环境工程以及材料科学与工程学教授杨冈博士认为,答案是使电子产品成为一个人“闷闷不乐”。

通过使用高尔夫球的电子设备能力的测试是符合形状的测试。“高尔夫球有很多酒窝,比大多数身体形状更为复杂。如果我们可以成功地将灵活/可拉伸的电子设备放置在高尔夫球上,那么我们应该毫无困难地将其合成在身体的任何部位上,”黄博士说。“但是,关键不是要以高尔夫球的形式获得电子,而是要像创可贴一样,将其呈现自然的形状并延伸。”

The challenge with this is that the human body takes on many shapes. Band-Aids alone come in multiple shapes. Also, manufacturing processes tend to lean toward simple 2D structures. Knowing what will happen to the shape and how it might affect the circuit once it’s on the 3D body is important. Fortunately, we already have a lot of knowledge and defined properties for materials that we know are safe for the human body. This data can be designed in software and simulated.

FEA and Simulation

使用诸如Dassault Systems的Simula之类的程序,Huang已经生成了许多已经制造并匹配模拟的形状。一些公司已经在使用可穿戴或灵活的电子技术开发商业产品:

- Reebok的检查灯 - 衡量对头部影响的示意力。

- L'Oreal的紫外线补丁 - 一个贴纸,让您知道紫外线受到了多少损坏您的皮肤。

- MC10 - WiSP—a wireless self-adhesive pad for health monitoring Glucose from sweat.

FEA和仿真软件正在加速市场和降低成本的时间。软件中的测试设计有助于迭代之间的时间,并预测将几何形状应用于动态3D表面时将如何变化和伸展。黄博士说:“来自西北大学的约翰·罗杰斯教授是这一发展的关键人物。”“他专注于设计,建模,仿真,优化,并负责该技术的设计,制造,系统集成和应用。”

"The human body shape is curvilinear, but the conventional electronics are flat," says Dr Huang. "There is clearly an incompatibility here, i.e., the conventional electronics, being rigid, cannot be wrapped conformally on the complex shapes such as heart or brain. One example is a Band-Aid which can be wrapped onto the finger without much difficulty, but if it is wrapped onto a finger tip, then the Band-Aid will have a lot of wrinkles and folds. The conventional electronics cannot be wrapped onto such complex shape, but stretchable electronics can since, at the place of wrinkles, the stretchable electronics can stretch itself like a rubber band."

The Difference Between Flexible and Stretchable

3 d打印电子的能力导致lot of talk about flexible electronics that use conductive inks on a flexible substrate. However, stretching that substrate adds a new level of complexity. Wires and inks might be able to form and flex without a problem, but they can’t be stretched. Once that challenge is solved, you still have the hard, brittle silicone chip that must be designed in a way so that it doesn’t break. 3D printing can deal with polymers and some metals, but not inorganic semiconductors like Silicon. Therefore 3D printing cannot be used to fabricate electronics (involving lot of inorganic seminconductors). To generate inorganic semicondictors, engineers must work together.

To solve this, “Mechanical and electrical engineers must work together simultaneously,” said Huang. “Normally, an electrical engineer would design a circuit and then have the mechanical engineer design a safe package. But stretchable electronics need to have both engineers working together.” In this case, the circuit and package are the same thing.

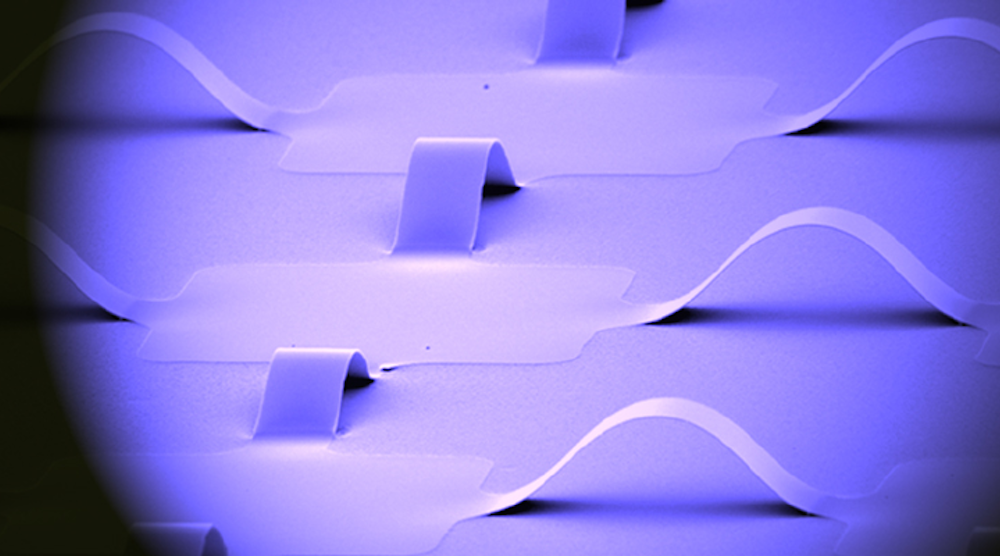

通过了解材料和电性能,可以将简单的电线放在可伸缩聚合物中电子结构之间的盘绕或蛇纹石。该技术称为空间填充曲线,因为曲线被用来填充空间。在设备的最大设计拉伸下,电线仍然会有一些曲线。此额外的曲线可确保电线不会断开或断开连接。为了进行这项工作,您需要找到一个不会变形的聚合物,而不是经过设计的伸长率。

想要:新弹性体

您还希望电路具有软弹性体以形成人体。但是,如果身体延伸到电线或连接的完整性会受到危害,则需要坚固或僵硬。黄已经开发了一种柔软的弹性体,但是当超过阈值时,将变得僵硬或抗拒进一步的拉伸。

The key to his development is built-in microstructures. As the elastomer deforms, the microstructures start to align, which will increase the amount of force needed to stretch it further. The elastomer is typically designed for 30% elongation, at 30% elongation, at which it will return to its original shape. However, elongation at 150% or greater could result in the microstructures aligning and crystalizing. At this point, the material would not return to its original shape. While this gives some stretch to the wires and substrate, the silicon chips, batteries, and other electronics are still rigid.

使硅胶拉伸

To make the entire system stretch, you start with a silicon wafer. This wafer leads to thin Silicon ribbons. Then polydimethylsiloxane (PDMS), a silicon-based organic polymer, is strained and bonded to the original thin silicon ribbons. Once the PDMS is removed, the thin ribbons are shown to become wavy. This provides a high semiconductor coverage area, but the wafer stretches less than 20%.

可以获得较大的“波浪”,以提高电路的拉伸能力(> 100%)。这是通过将覆盖面积减少到约25%来实现的。一旦技术可以拉伸,就没有任何终点 - 包括使科幻小说成为现实。例如,在节目“黑镜”中,多集描绘了作为相机起作用的目光接触,或者可以为一个人的视野增加增强现实。在节目中,这些联系人允许角色录制,共享或播放他们所看到的所有内容以及更多内容。这可能是从2008年8月的《科学杂志》上启发的Nature. That issue featured a paper on an electronic camera that is able to take the shape of a human eye, one that could someday work on a contact lens.

Today, however, most of this technology is going into medical wearables, not entertainment. Cost is a factor here, as well as the fact that some of the technology is still being researched or is in testing. Much of the testing with the materials has worked out well. In the design stage, there was a great concern about stress concentrations and fatigue failure. To combat stress concentrations, it is important to keep the strain on the silicon as small as possible. A safety factor is built into the silicon. A device is designed so that only 10% of the overall fracture strength will ever be put on the silicon during its operation.

For fatigue, Huang’s lab and other companies that use this technology have tested materials and designs over 100,000 cycles without incident. When exceeding this number of cycles, stress and fatigue no longer pose much of a concern. Before a wearable sees over 100,000 cycles, it will start to lose contact with the body.

Adhesives for the Body

Most failures are not because of a mechanical or electrical problem, but because the device loses contact with the skin. This is not due to lack of adhesive technology, but rather, the fact that the skin generates new cells. The old cells that are attached to the medical device won’t continue to have enough contact to make accurate readings, or even stay on the body, after a week or two.

此外,可以减少电力的粘合剂signals between the skin and device. The devices being designed often do not use adhesives. They are very thin, following the topology of the skin so well that the Van Der Waals forces are actually strong enough to keep the device on the body. These forces are enough to keep a medical device on through normal day-to-day activities.

If you were to take a shower longer than 20 minutes, swim, or have a rigorous workout, however, an adhesive would still be needed. By using Van Der Waals forces, a device could be easily removed and reapplied without issues of the adhesives compatibility with the patient’s skin, needing to clean old adhesive off, or needing to add more adhesive.

As this technology grows and cost is reduced, sophisticated wearables could make it into entertainment. Huang has already designed a stretchable battery. But for now, flexible and stretchable electronics and batteries can be easily attached without adhesives, and are poised to change the way we think of medical devices. An EKG can now be smaller than a fingernail and send updates to your phone.

Imagine a Band-Aid telling you when the wound it is covering has healed. A sticker might tell you when to get out of the sun, or when to get more of it. Imagine having a sticker that is actually your watch, and that connects to your phone, and is powered by another sticker that’s a battery. As the gap between sci-fi and reality closes, we must realize that our imaginations might become our biggest limiting factor.