According toStatista阿布,全球汽车产业将增长t $9 trillion by 2030, with new vehicle sales accounting for about a 38% slice of that pie. Although the global COVID-19 pandemic may have impacted certain sectors over the past few months, Frost & Sullivannotesthat a decline in car sales typically last only two years, rallying to pre-recession levels within four years, based on data from the last 50 years.

确实,汽车空间是一个令人兴奋的地方,但行业和技术持续不断破坏can be challenging. Moving large parts across the factory floor, unforeseen safety incidents, and inconsistent transport systems often slow down production and cause loss of production efficiency.

However, what if a factory could better meet these evolving demands? What does it take to digitize automotive manufacturing production processes to better control output quality and quantity? What does a true smart factory look like and how does it work at-scale?

The Promise of Digital Transformation

Halfof automotive manufacturers say that to maintain operations by 2030, they must enhance their organizations with digital technologies. Considering this broad industry recognition of the need to pursue digital-transformation efforts, traditional automotive manufacturers are working to digitize antiquated manual monitoring systems in their assembly process.

Over the past 50 years, the automotive industry has collectively invested数十亿企业系统,自动化解决方案和高级产品技术的美元。下一步,汽车公司必须采用正在重新定义制造流程并使其他具有行业4.0功能的行业的数据和技术前进公司提供的优势。此外,必须定期测量和验证数字化计划,以使汽车制造商清楚地看到其努力的真实价值。

Identifying the Highest-Value Use Cases

To realize the most compelling business outcomes for potential digital-transformation initiatives, automakers must first identify and prioritize which use cases are most critical to overall success and will deliver the highest ROI. Realizing the value of digital-transformation investments before they begin—by identifying specific use cases and the associated ROIs—manufacturers will be able to weigh the cost vs. benefit of their digital-transformation initiatives and pursue them to fruition.

汽车行业中有四个主要的高价值用例,用于数字化转型:可扩展生产管理,资产优化,实时运营智能和数字劳动力生产率。

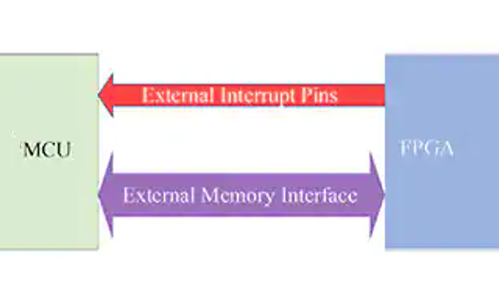

Integration between operational technology (OT) and information technology (IT) is critical to realizing and executing the initiatives that must be undertaken to achieve those four use cases, which ultimately lead to productivity gains at scale. When OT and IT are integrated, automakers possess an improved understanding of factory operations, often resulting in a significant reduction in machine downtime, improved yield, and other various benefits.

在质量控制和制造优化方面,工业互联网(IIOT)是OT和IT集成的一个很好的例子。IIOT使汽车制造商不仅可以监视打ic和故障的生产,而且还可以通过更多的数据访问来驱动企业的增长。IIOT传感器在整个商店地板的机器和工作站上进行战略性放置,分析瓶颈,提供数据以支持预测性维护建议,并以更有效的方式重新安装工作站任务,并改善质量和安全问题。

By using scalable analytics, automakers can process the vast amounts of shop-floor data provided by IIoT sensors to fully optimize the entire production line. For example, vehicle parts may travel through multiple facilities before being fully assembled. OT/IT integration allows automotive production managers to maintain complete visibility of each part’s assembly journey through the supply chain. Data from shop-floor equipment, provided by IIoT sensors, can be analyzed to predict how any changes will impact overall production and quality control.

以前,只有在实现这些计划后,才能收集许多用于验证数字转化计划的数据,例如OT/IT集成和IIOT。幸运的是,由于新的数字技术,包括增强现实(AR)和数字双胞胎,汽车制造商可以在虚拟环境中测试潜在的新系统,然后再将资源部署在现实世界中。

一旦汽车制造商确定了特定的用例和投资回报率,下一步是什么?

全栈IIOT解决方案提供商可以设计和支持汽车制造商的整个IIT生态系统,从车间机器到顶层控制系统,再到云计算功能。如果汽车制造商不确定从哪里开始他们的数字化转型旅程,或者如何权衡成本与数字化计划的收益,他们应该与如此经验丰富的提供商合作,以更好地了解其行业4.0的道路。

全堆栈解决方案提供商可以大规模对数字转换项目的重要部署,并确保随着时间的推移这些项目的相关性。物联网解决方案提供商不仅使数字转换工作的初步部署更加容易,还使汽车制造商能够进一步采用创新的新技术,例如Edge Computing,AR和Digital Twins。与消费者物联网(Itot)的寿命短,只有几年的时间,必须对IIOT进行量身定制以符合特定企业的独特需求,以确保其能够经受时间的考验。

在选择解决方案提供商时,请确保不仅具有广泛的技术专业知识与合作伙伴交流,还可以完全了解汽车行业的独特需求。这样可以确保他们可以充分量身定制IIT计划以实现长期目标。

The key to measuring IIoT success is knowing exactly where the path to digital transformation begins and where it will lead. Organization should fully understand the benefits provided by scalable IIoT when it comes to enabling enterprises with Industry 4.0 capabilities needed to remain competitive. With this, automakers can accurately weigh the cost versus benefits of their digitization initiatives and see them through to fruition. Often, the benefits of delivering increased value to consumers today in the form of higher-quality-control standards and ensuring strategic competitive advantages in future production outweigh the costs.

Keith Higgins is VP of Digital Transformation atRockwell Automation.

.png?auto=format&fit=crop&h=139&w=250&q=1)