What you’ll learn:

- SMT在PCB制造中的重要性。

- SMT如何对PCB制造商有益。

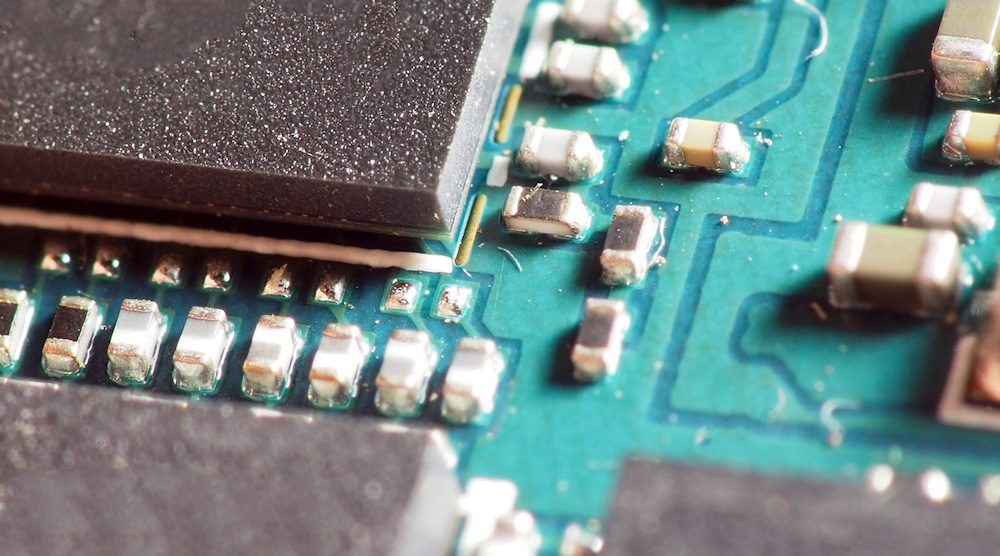

Have you opened an electronic device and found some small component networks? You see pieces of different elements placed on your mobile, laptop, and microwave circuit boards, etc. Instead of using common equipment, the printed-circuit-board (PCB) manufacturer installs advanced components on the board surface using surface-mount technology (SMT).

什么是SMT?

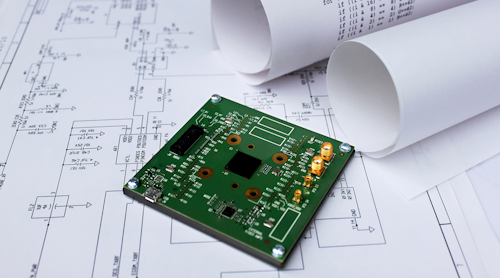

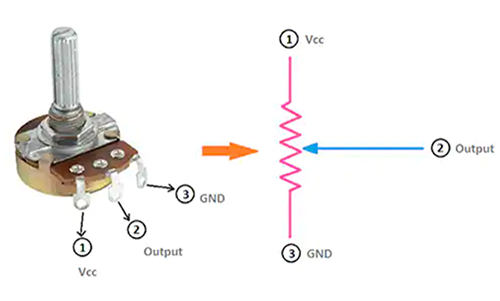

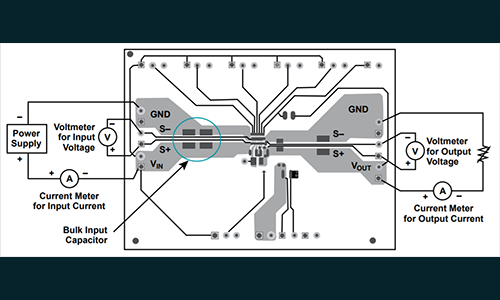

SMT connects electronic components—surface-mount devices (SMDs)—to the top and bottom surface of a PCB. Surface technology replaces pressing-fit or wave-solder, through-hole technology(见图). Thanks toSMT PCB technology, designers are able to create smaller assemblies. SMT is a direct method that involves just placing and positioning the PCB component on the board.

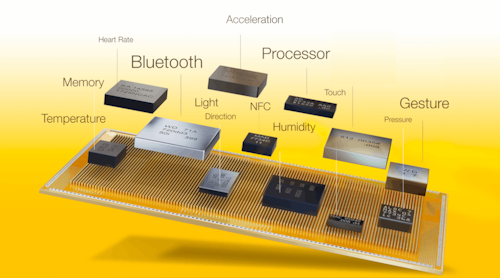

SMT has a number of advantages including:

- Lower manufacturing costs:SMT允许较小的PCB设计生产,从而减少生产成本。SMT将尊重以下事实:放置正确的元素至关重要。

- Improved efficiency:另一个解释为什么许多PCB生产商更喜欢SMT是更好的工作效率。使用SMT,可以迅速将电路组件转换为一个素数,这与通常需要时间的压制拟合技术不同。

- SMT is easier to work with:With SMT, the configuration is clearer—the mounted SMT board doesn't require a lot of technical knowledge. Essentially, the SMT panel’s layout is simpler than that of other methods.

- Fewer defects:SMT technology also is beneficial in terms of managing errors. SMT facilities can easily cope with the necessary changes and modify the same. Thus, designers can create boards with little concern regarding errors during the process.

- 上电磁兼容(EMC)效率:With SMT, it’s possible to achieve a lightweight bundle along with lower lead activation. In this case, the electromagnetic structures possess greater efficiency.

- Automated assembly:Most SMT parts can be easily installed on circuit boards using automatic pick-and-place equipment. The high-volume section, such as passive components, is loaded from the roll, while the other area is loaded from the tube feeder or tray. This is significantly different than the pin through-hole (PTH) component that often must be collected manually.

- 更好的电气性能:由于它们的尺寸,SMT零件比PTH零件更适合板。因此,您最终也会获得较短的信号路径。这会导致更好的PCB信号完整性和更少的热量,而不是整孔部分。

Difference Between Through-Hole and SMT

Some key differences exist between board creation technology that uses through-holes versus SMT. For example, SMT removes restrictions in spacing due to through-hole connections. Through-hole components typically have higher production costs relative to SMT.

On the flip side, SMT requires different and usually more sophisticated design and production skills. The lower production cost is offset by the high capital investment into machines that can handle SMDs. In addition, SMT components may have a higher number of pins than lead-based, through-hole components.

SMT components are more compact; hence, the higher component density of an SMT design as well as a lighter-weight board. Furthermore, because the board is more compact, it helps reduce electrical noise as well as susceptibility to electromagnetic interference (EMI). On top of that, eliminating holes for device connections can in turn reduce the number of holes needed for a PCB, thereby speeding production.