This article appeared inMicrowaves & RFand has been published here with permission.

你会学到什么:

- Why silicones have the right balance of properties for 5G electronics.

- Where silicones are used in consumer electronics and 5G networks.

- 有机硅如何解决粘附,封装,涂层和EMI屏蔽的挑战。

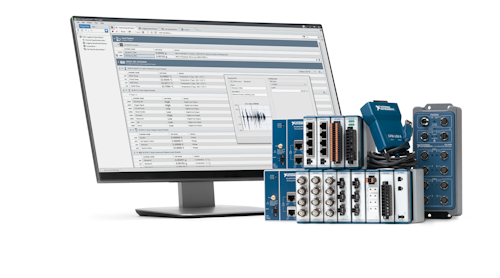

The 5G ecosystem includes consumer devices, telecommunications equipment, cloud computing, and data centers. Across this ecosystem, new designs are disrupting existing technologies because 5G’s greater power densities produce increased levels of heat(图。1)。In addition to thermal management, electronic designers need shielding against electromagnetic interference (EMI) due to crosstalk between numerous adjacent circuits. Environmental sealing also is required because many 5G devices and equipment are exposed to outdoor weather conditions.

For electronic designers, the challenges include adhesion, encapsulation, coating, and molding. Materials that can meet 5G’s tough requirements are in demand, but not all chemistries have the right balance of properties.

Material Selection and Electronics Protection

许多可用的保护材料提供了具有重要权衡的优势。例如,丙烯酸件固化迅速用于高效的电子组件,但在高温下软化。氨基甲酸酯和聚氨酯非常坚硬耐磨机械磨损;然而,这些材料不提供通过快速和不均匀的加热和冷却引起的应力的充分浮雕。

然后存在全环氧树脂,可以抵抗湿度,但更容易发生裂解,可能导致粘合剂,密封剂和涂层失效。聚对比亚烯是化学惰性,但在电子组装期间仅支持有限的吞吐量。这是智能手机和笔记本电脑等大规模产品的限制。

相比之下,硅树脂有吸引力的资产of properties and support high-volume manufacturing. These elastomers resist moisture, chemicals, and contamination while remaining soft and flexible. Their hydrolytic stability is especially important because 5G will mean installing more towers, base stations, and transmitters in locations with high humidity, rain, or snow(图2)。

重要的是,硅氧烷可以抵抗5g的较高温度,同时提供更长持久的耐热性,而无需在性质中显着损失。随着它们的低模量,硅氧烷也可以减轻一些应力,导致材料以不同的速率在不同的速率下扩大和收缩,因为它们不同的热膨胀系数(CTES)。

此外,硅氧烷树脂在许多基材上提供良好的粘附性,通常不使用底漆以获得更高的生产效率。在此之上,有机硅粘合剂,密封剂,涂层,密封剂和EMI屏蔽能够支持自动分配和更有效的固化系统。在室温下固化的硅氧烷可以消除对烤箱的需求,减少能量费用并支持更大的可持续性举措。

Silicone resins with low levels of volatile organic compounds (VOCs) also can meet regulatory requirements and address environmental health and safety (EHS) concerns. From 5G smartphones to advanced driver-assistance systems (ADAS), these elastomers support consumer devices.

5G消费电子产品

智能手机设计师指定硅氧烷,因为这些材料可靠地散热,具有防裂,应力缓解和减震性能,以防止磨损和撕裂。硅氧烷也将耐高温和低温的耐受低固化收缩,这是智能手机的重要考虑因素,显示面板和盖板之间的空气间隙需要防水密封。

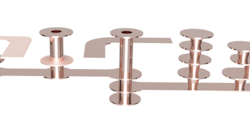

具有优异的光密度,一些有机硅与遮光罩一起使用,以帮助阻止不需要的照明(图3)。Other silicones are employed with light guides because they combine high luminous transmittance, low haze, and low scatter with resistance to ultraviolet (UV) light. Silicone adhesives for flexible, foldable displays can be applied directly to thin metal surfaces and form an elastic layer, or inner hinge, that helps to protect the display from damage caused by folding and unfolding.

其他硅胶应用目标智能手机配件和5G Smartwatches。例如,硅胶热粘合剂在智能手机充电器内使用,这往往会迅速加热。防水智能手机连接器的可靠粘合也需求。

含有硅氧烷,电缆连接器的粘合和密封可以将底漆的粘合性与瞬间绿色强度结合,以便更好地粘附和较少的浪费可重换性。这些特征对于5G Smartwatches-Compact设备非常重要,该芯片具有产生显着热量的芯片,并且可能需要在产品组件期间返工或去除残留物。对于环境密封,高稠度橡胶(HCR),铂金催化剂到达即可使用。用于SmartWatch带的液体硅胶橡胶(LSR)支持高批量成型,并具有出色的加工性能以及短循环时间。

Other 5G devices that can benefit from the use of silicones are true wireless stereo (TWS) earphones. They need charger protection that meets UL 746C for ignition characteristics and UL 94 V-0 for vertical burning. Because they’re worn outdoors and compressed repeatedly, TWS earphones also require environmental sealing with resistance to compression set.

设计ers of virtual-reality and augmented-reality (VR/AR) products like how silicones are lighter than glass and can have high luminous transmittance and low haze and scatter for use with optically clear lenses. In drones, silicone thermal gels dissipate heat without post-cure oil contamination. Unmanned vehicles can utilize silicone adhesives that combine EMI shielding with good mechanical properties for strong bonds to a variety of substrates.

The 5G consumer electronics market includes advanced driver-assistance systems (ADAS) for automobiles. Silicone conformal coatings have the abrasion resistance and toughness that’s needed to protect rigid or flexible printed circuit boards (PCBs) from scratches. When EMI-shielding adhesives are required, electrically conductive silicones support flexible joints and have high elongation to avoid breaking(Fig. 4)。ADAS设计师还可以选择用于组装更大模块的硅胶粘合剂。

硅胶密封剂提供模块级保护。组件级解决方案用于电动车(EV)电池组和ADAS传感器,用于光检测和测距(LIDAR)和雷达。由于其良好的介电性能,硅胶百科提有助于保护连接器,电源供应商,传感器,变压器,放大器和高压电阻包。

Inside of computer laptops, silicones are used at the PCB level to help dissipate high heat from central processing units (CPUs) and graphics processing units (GPUs). They’re also used with other board-mounted electronics and heat sinks. Silicone thermal greases support lidless die designs for closer component packaging and resist pump-out that can impede dispensing.

Silicone adhesives for metal laptop frames have a viscosity that makes it easy to apply them to the etched areas of thin stainless-steel sheets used beneath foldable displays. Molding with liquid silicone rubber (LSR) produces keypad domes with longer fatigue life. Through compression molding or vacuum lamination, silicone encapsulants protect a laptop’s light-emitting diodes (LEDs) and resist both high heat and scratching.

Ultimately, 5G’s greater reliability may be even more important than its higher speed and larger capacity. To become the network of everything, 5G requires a level of service that can support always-on technologies ranging from the safety systems in self-driving cars to seamless video downloads from flexible, foldable computers.

With consumer electronics, silicones already support greater reliability at more than just the device level. From thermal management and EMI shielding to adhesion, coating, and encapsulation, silicones also protect the sensitive electronics that form the backbone of cellphone and data carrier networks.

Carrier Networks and Heat Dissipation

毫米波(mmWave)网络5 g devices and equipment need to support high-frequency communications plus 2G, 3G, and 4G mobile-phone services at 800 to 2100 MHz. As more 5G networks become available, demand for 3.3- to 5.0-GHz communications will increase as existing 5G-enabled devices begin to use previously unavailable features.

mmWave networks will provide more bandwidth, but 5G’s higher data rates are offset by its limited connection range. Consequently, carrier networks will need many small cells or mini base stations to ensure coverage. Furthermore, carrier networks will require large cells or macro base stations to provide basic broad coverage using either 4G or 5G.

In addition, carrier networks must meet the demands of digital beamforming and massive MIMO. Unlike traditional multiple-input, multiple-output (MIMO), massive MIMO adds many antennas to a base station. Because these antennas may have up to 256 channels, it’s especially important for designers to use smaller components and consider both energy efficiency and thermal management. With high levels of semiconductor integration, a single module may contain a transceiver, power amplifiers (PAs), filter, and antennas.

Today, a common design approach is to use a low-loss substrate combined with a flip-chip device and on-module EMI shielding. Silicones filled with metal or metal-coated particles can provide reliable shielding along with dependable electrical conductivity.

The architecture of carrier networks presents another design challenge. With their large antenna arrays and remote radio heads (RRHs), active antenna units (AAUs) have large power outputs that generate significant amounts of heat. Baseband units (BBUs), centralized units (CUs), and distributed units (DUs) also require effective heat dissipation. For electronic designers, more optical module connections and more server demands must be considered, too. Silicones are commonly used to coat optical fibers, but these elastomers have many other optical applications.

In optical transceivers, for example, silicone thermal gels are used to dissipate potentially damaging heat. As thermal-management materials, they transfer heat from the transceiver’s core components to a metal shelter that serves as a heat sink.

Typically, the transceiver’s heat-generating components include a microcontroller (MCU), transmitter optical subassembly (TOSA), tunable laser, integrated circuit (IC), and signal processor. During module assembly, silicone adhesives are able to combine strong bonds with both reliable EMI shielding and controlled levels of VOCs. Silicone encapsulants for optical splitters can resist the formation of microcracks caused by environmental stresses and that propagate over time.

无线接入网络和核心网络

设计ers of radio access networks (RANs) also must overcome thermal management, EMI shielding, and other reliability and performance challenges. In addition to providing dependable access, RANs need to coordinate network resources among many wireless devices regardless of frequency.

At mmWave frequencies, 5G’s data-carrying capacity is extreme. At lower frequencies, 5G still provides significantly higher data rates than 4G. WiGig, a type of wireless local area network (WAN) that uses mmWave frequencies, offers significantly greater speeds than Wi-Fi but will require many small cells. With the proliferation of so many mini base stations, electronics manufacturers will need materials that support high-volume assembly.

The 5G AAUs for RANs have significantly greater power outputs than with 3G and 4G equipment. Silicone thermal greases can provide effective heat dissipation, and two-part curable silicones gels are a good choice for both AAUs and remote-radio-unit (RRU) power modules. For EMI shielding, softer silicones are used in gasketing because of their compressibility.

Silicone thermal gels with high thermal conductivity (TC) provide thermal management for base stations. They’re used with power-supply rectifier modules, power amplifiers, the RRU, or an AAU chipset, and between BBU chips and the heat sink. Silicone sealants and adhesives are applied to antenna covers, and silicone conformal coatings are used with AAU PCBs(Fig. 5)。

The 5G core network uses a cloud-aligned, service-based architecture (SBA) that spans all functions and services, including security. In terms of design considerations, a core network is characterized by network slicing, software-defined networking (SDN), network function visualization (NFV), and multi-access edge computing (MEC).

通过网络切片,通过特定的服务质量(QoS)特性的切片分配无线电资源。NFV虚拟化核心网络功能以支持不同的切片,例如智能手机和汽车。为了实现低延迟和成本节约,核心网络的某些功能将靠近MEC部署。

Silicone thermal greases are used with MEC equipment and servers. These heat-dissipating greases are also applied in the design of lidless CPUs and GPUs. Reworkable thermal gels for Ethernet switches and routers can use bare dies to support package size reductions and improve power management. The benefits of bare dies include more reliable operation at extreme temperatures and greater mechanical ruggedness. Silicones are also employed with switch-on-a-chip (SOC) technology for faster speeds.

不断发展的5G生态系统

As the 5G ecosystem continues to evolve and expand, silicone elastomers will play an even larger supporting role. Electronic designers have a choice of materials, but silicones provide an attractive balance of properties and can address challenges, such as thermal management, which are particularly important to successful 5G deployments. By choosing the right partner, designers and electronic manufacturers can find the right solutions as they continue to grow with the larger 5G ecosystem.