What you’ll learn:

- What are the key tradeoffs, such as resolution, ruggedness, cost, etc., made between industrial and professional cameras?

- How advances in camera technology impact different industries.

The move to digital imaging sensors has created several options for system developers. For example, during the past 15-20 years, as digital technology improved, several industrial and B2B organizations started to switch from industrial cameras to professional (DSLR/mirrorless) cameras.

But the factors influencing the camera choice of an industrial manufacturer seeking to undertake a quality-inspection process in a factory are vastly different to those of an e-commerce firm seeking to capture images for a website, which again are vastly different to a company creating drones for mapping or archaeological analysis.

那我们现在在哪里?为了回答这一点,我们研究了系统开发人员面临的一些重大权衡,以及确定哪些行业应考虑转变的最新技术进步。

Tradeoffs

工业和专业摄像机在几种方面有所不同,并且每种相机都是(或应该)整体设计的,而不仅仅是传感器。设计精良的相机 - 无论是XCG-CG510之类的工业摄像头或像Alpha ILCE 7R这样的全镜相机 - 将选择/设计每个组件以从传感器中提供最佳图像:适应住房,适应住房,镜头,处理器,传输标准…

But there are tradeoffs. Some of the biggest are resolution vs. sensitivity, ruggedness vs. size/weight, the need for automation and synchronization, as well as cost, speed, and the lenses available.

Resolution vs. Sensitivity

Resolution is typically the first requirement specified in an imaging system. Indeed, most (albeit not all) applications want as large a resolution as system cost and processing capabilities allow.

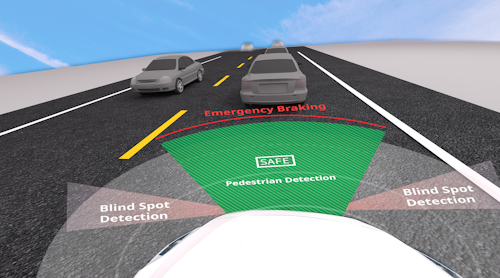

A higher-resolution system can capture a larger area without losing essential details. For example, in ITS and security applications, a single wide area shot would still clearly distinguish the number plate, or an individual’s face. In drones used for mapping or archaeological surveys, this allows for fewer images to be taken while still capturing an entire area, and still provide the fine detail to enable an individual region of interest to be zoomed in on to see greater detail.

在传感器级别上,有两种增加分辨率的方法:增加像素密度或增加传感器的大小。

Increasing pixel density makes sense in industrial camera applications where lighting conditions are well-controlled, and where the cost of full-frame cameras remains prohibitively high.

However, image quality isn’t just about the overall pixel count. There’s a limit to how far you can take this approach.

通过减小像素大小,您可以减少到达每个像素的光量,从而降低了相机的灵敏度并增加噪声。走得太远,图像变得降低了。

Just such a scenario has played out in the evolution of global-shutter CMOS (GS CMOS) sensors used in industrial cameras. When moving from the first to the second generation, pixel size shrunk by 41% (from 5.86 µm to 3.45 µm). This delivered the improved resolution required by some industrial manufacturers, but it also decreased sensitivity that could negatively impact other applications. As a result, the third generation of sensors looked to find a middle ground, increasing pixel size to 4.5 µm to better balance resolution and sensitivity.

And while new technologies are addressing this balance—for example, process technologies that flip the photosensitive and wiring layers to allow more light to reach the pixel—a larger sensor will deliver a better image quality. This is particularly evident if used outdoors at night and in poor conditions, where lighting conditions vary.

This means the 1-in. format (12.8 × 9.6 mm) or smaller formats used in industrial cameras designed for standardized lighting conditions aren’t ideal in other settings. Instead, APS-C (23.6 × 15.6mm) or better still, full-frame (36 × 24 mm) sensors found in professional mirrorless cameras, will produce much higher image quality.

为了将这些测量值放在上下文中,全帧摄像机的传感器区域大约是APS-C摄像头的两倍,大约是1英寸的7倍。传感器(Fig. 1).

Ruggedness vs. Weight

工业摄像机通常置于巨大的压力下,因此旨在应对。旨在在工厂地板上设计的相机应该能够应对10 g(20至200 Hz)的振动以及高达70 g的冲击。

However, this adds weight and bulk to the camera, making it inapplicable for a drone used for mapping (it would significantly shorten flight time).

This means professional cameras, such as the Alpha ILCE 7R, which are considerably lighter than their industrial counterparts, are used instead. And by utilizing the smaller APS-C sensors, camera size and weight can reduce further—albeit with reduced resolution and/or sensitivity.

如果我们再次查看无人机,尤其是像映射这样的应用程序需要长时间飞行时间,那么重量可能至关重要。确实,在少数情况下,我们的相机重量仅为600 g。无人机并不是尺寸重要的唯一市场。多相机捕获系统(例如在电子商务中使用的系统)可以具有20或30个单元,使单位尺寸的较小增加在系统级别上显着。

As such, in applications where size matters, APS-C cameras like the Alpha 6600 tend to be integrated.

However, the weight of full-frame camera systems has dropped considerably to the point where they too fall below 600 g. For example, this past September saw thelaunch of what’s currently the lightest full-frame camera system(body and lens). It weighs a mere 510 g, which is just 1% more than the Alpha 6600 APS-C camera commonly used with drones.

That’s not to say ruggedness isn’t an issue for B2B applications. ITS and security cameras are designed to be left outdoors in all weathers, in casings that are subject to vibrations from wind and passing road traffic. Hence, they have often used industrial and/or block cameras, connecting them via the Gigabit Ethernet interface.

这也被解决(尽管不是尘埃rial levels), though. Professional cameras are beginning to use monocoque constructions, moisture-resistant designs, and more rugged housings that better protect the unit’s electrical contacts and better absorb the shock from vibration and physical impacts.

The Need for Automation and Synchronization

自动化在许多B2B应用中至关重要。它是工业应用的主要驱动力。最新的传感器不仅能够在外部触发器(例如激光传感器或GPS定时芯片)上触发,还可以通过相机本身监视感兴趣的区域并在正确的时间进行射击。

This has been particularly useful in applications such as traffic (speed/red-light) cameras. While software development kits (SDKs) for DSLR and mirrorless cameras have been available for well over a decade, they were, until recently, relatively basic. This is changing, too—they now allow for control of virtually every facet of the camera.

A good example of how they can be used is for a mapping drone. Here, it’s possible to pre-plan a route and have the SDK control the trigger based on timing or GPS location, and to adjust the aperture of the lens according to the light levels. Therefore, upon landing, the SD card is removed, and the images subsequently can be stitched together on a computer.

SDKs are frequently only available for use with higher-end (industrial/ full-frame professional) cameras, though, rather than for APS-C-based cameras. It should also be noted that not all SDKs are created equally, and companies are using them to gain a competitive edge in a fast-growing industry

例如,在欧洲,我们估计B2Bmarket for mirrorless and DSLR cameras is in the region of €300 to 350 million. This means that as well as simplifying the automation process, SDKs include application libraries to speed development and support is given—in some cases with engineering resources available. As such, the standard of the SDK (and its application library/support) should be considered when selecting a camera.

One example of such increasing functionality isSony’s版本1.03 SDK。这是无反光镜全帧摄像机启用多相机触发的SDK。

Applied to ITS, this means images from multiple angles can be captured, providing the ability to prove that both a traffic offense happened, and who was driving.

但是,显示两者的单个图像通常还不够。来自German state Baden Württemberghas stated that two-thirds of its offenses go unprosecuted because the driver can’t be reliably (and cost-effectively) identified. And in New South Wales, Australia, a system to detect mobile-phone use while driving nearly didn’t go ahead because it was feared the起诉时间和费用太高(Fig. 2).

Other Factors

The aforementioned factors obviously aren’t the only tradeoffs to make when considering a camera for a B2B application.

可以说,成本是影响每个权衡的最大因素之一。这就是工业模块使用较小传感器的原因。在大多数应用中,部署满足工业摄像机坚固性要求的全画幅摄像机将非常昂贵。

镜头阵容也是一个重要的consideration, with industrial modules having very few options and rarely allowing for an integrated lens design without significant expense. Conversely, a good full-frame professional camera will, in some cases, have 50+ lens options that can be deployed.

另一个是焦点速度,专业相机的速度比工业单位更快。在相机或受试者迅速移动的应用中,例如无人机或ITS,可能是必不可少的。

Conclusion: Which Industries Have Reached the Tipping Point?

几个权衡会决定组织选择的相机。但是,最近的技术进步意味着可以最好地平衡分辨率,敏感性,坚固性,重量,自动化的相机,当然,任何给定项目的成本要求都可能已经改变。

对于某些人来说,专业相机的坚固性和自动化的进步意味着它们可以取代更昂贵,更敏感的工业版本。对于其他人来说,低重量的施工方法将使它们从APS-C迁移到高分辨率的全帧摄像头。每个行业都是独一无二的,平衡了这些权衡。正如我们上面所述的那样,某些处于或达到该转折点的部门是:

- ITS:加强的坚固性,再加上新的SDK功能,从而实现了多相机控制,从而使工业摄像头能够获得提高灵敏度和焦点速度的好处。

- Security:Like ITS, the need to capture footage outdoors, in the dark, and in poor conditions means a more sensitive camera is essential. And while discretion (and therefore size) can be paramount, the latest full-frame cameras are as small as APS-C modules yet offer significantly increased resolutions.

- E-commerce:Resolution and sensitivity are less of an issue for e-commerce; images tend to be smaller and lighting is controlled. However, the advances in SDKs, and in particular the ability to have multiple cameras capture products from multiple angles from a single setup, is compelling.

- 无人机:Not all drones need to move from APS-C to full frame. But the improved resolutions and/or sensitivity, coupled with the wider range of lenses, make a move prudent here, especially when coupled with the recent reductions in full-frame camera size and weight that enable them to be used for mapping, scientific, security, and content-creation drones.